|

INSTRUMENT CLUSTER INPUT/OUTPUT CHECK MODE

id092200801700

Check Code Table

|

Check code |

Checked item |

Related item |

|---|---|---|

|

01

|

Buckle switch (driver-side)

|

Buckle switch (driver-side)

|

|

04

|

Door switch

|

• Ignition key illumination

• Key reminder warning buzzer

• Lights‐on reminder warning buzzer

|

|

08

|

TNS relay

|

• Lights‐on reminder warning buzzer

• Each illumination

|

|

12

|

Speedometer

|

Speedometer

|

|

13

|

Tachometer

|

Tachometer

|

|

14

|

Buzzer

|

Buzzer

|

|

16

|

Fuel‐level warning light

|

Fuel‐level warning light

|

|

22

|

Fuel gauge sender unit

|

Fuel gauge

|

|

23

|

Fuel gauge

|

Fuel gauge

|

|

25

|

Water temperature gauge

|

Water temperature gauge

|

|

26

|

LCD

|

LCD

|

|

31

|

Key reminder switch

|

Key reminder warning buzzer

|

|

33

|

Turn/hazard signal

|

Turn/hazard indicator buzzer

|

|

55

|

Dimmer cancel switch

|

Instrument cluster illumination

|

|

58

|

Buckle switch (passenger-side)

|

Buckle switch (passenger-side)

|

|

59

|

Fuel system signal

|

Fuel gauge

|

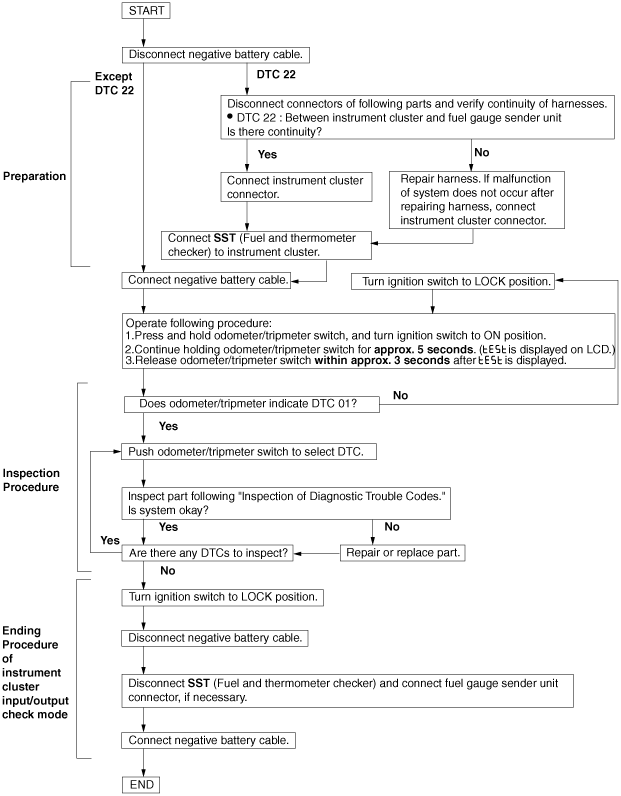

Operating Order

am6zzw00004752

|

Checking Order

|

Priority order of inspection |

IG switch position |

Check code |

|---|---|---|

|

1

|

ON

|

22

|

|

2

|

01, 04, 08, 12, 13, 14, 16, 23, 25, 26, 55, 58, 59

|

|

|

3

|

LOCK

|

31, 33

|

Inspection of Check Codes

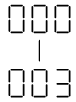

Check code 01

|

Check code 01 |

Buckle switch (driver-side) on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Unfasten driver‐side seat belt. (Buckle switch on.)

|

|

Go to next step.

|

|

|

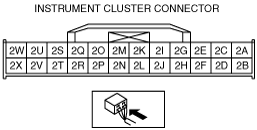

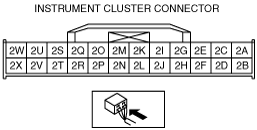

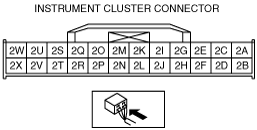

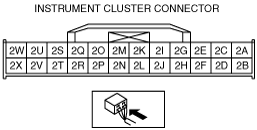

Measure voltage at instrument cluster terminal 2G.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|||

|

2

|

Fasten driver‐side seat belt. (Buckle switch off.)

|

|

Measure voltage at instrument cluster terminal 2G.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 04

|

Check code 04 |

Door switch on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Open driver‐side door. (Door switch on.)

|

|

Close driver‐side door, then go to next step.

|

|

|

Measure voltage at instrument cluster terminal 1J.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|||

|

2

|

Close driver‐side door. (Door switch off.)

|

|

Measure voltage at instrument cluster terminals 1J.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 08

|

Check code 08 |

TNS relay on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Turn headlight switch to TNS position. (TNS relay on.)

|

|

Go to next step.

|

|

|

Measure voltage at instrument cluster terminal 2K.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|||

|

2

|

Turn headlight switch off. (TNS relay off.)

|

|

Measure voltage at instrument cluster terminal 2K.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 12

|

Check code 12 |

Operation signal to speedometer |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 12.

|

|

Speedometer needle moves full scale then returns to 60 km/h or 60 MPH.

|

Speedometer is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

|

—

|

|||

Check code 13

|

Check code 13 |

Operation signal to tachometer |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 13.

|

|

Tachometer needle moves full scale then returns to 3,000 rpm.

|

Tachometer is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

|

—

|

|||

Check code 14

|

Check code 14 |

Operation signal to buzzer |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 14.

|

|

Buzzer sounds.

|

Buzzer is okay.

|

|

|

Buzzer does not sound.

|

Replace instrument cluster.

|

|||

Check code 16

|

Check code 16 |

Operation signal to fuel‐level warning light |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 16.

|

|

Fuel‐level warning light turns on and off three times.

|

Fuel‐level warning light is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

Check code 22

|

Check code 22 |

Fuel level signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|---|---|---|---|

|

1

|

Select check code 22 with fuel gauge sender unit connector disconnected.

|

|

Go to next step.

|

|

Other than stated above.

|

Replace instrument cluster.

|

||

|

2

|

Connect instrument cluster terminals 2D and 2M.

|

|

Go to next step.

|

|

Other than stated above.

|

Replace instrument cluster.

|

||

|

3

|

Using SST (Fuel and thermometer checker) or resistor, input 20 ohms between instrument cluster terminals 2D and 2M.

|

|

Go to next step.

|

|

Other than stated above.

|

Replace instrument cluster.

|

||

|

4

|

Using SST (Fuel and thermometer checker) or resistor, input 60 ohms between instrument cluster terminals 2D and 2M.

|

|

Go to next step.

|

|

Other than stated above.

|

Replace instrument cluster.

|

||

|

5

|

Using SST (Fuel and thermometer checker) or resistor, input 100 ohms between instrument cluster terminals 2D and 2M.

|

|

Inspect fuel gauge sender unit.

|

|

Other than stated above.

|

Replace instrument cluster.

|

Check code 23

|

Check code 23 |

Operation signal to fuel gauge |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 23.

|

|

Fuel gauge indicates in following order every 2 seconds.

• F→1/2→E→F (fixed)

|

Fuel gauge is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

|

Replace instrument cluster.

|

|||

Check code 25

|

Check code 25 |

Operation signal to water temperature gauge |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Wait for 2 seconds after selecting check code 25.

|

|

Water temperature gauge indicates in following order for every 2 seconds.

• H→Center→C→H (fixed)

|

Water temperature gauge is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

|

Replace instrument cluster.

|

|||

Check code 26

|

Check code 26 |

LCD indication |

|||

|---|---|---|---|---|

|

INSPECTION |

INDICATION |

SITUATION |

ACTION |

|

|

Select check code 26.

|

|

• Display is normal.

• Warning and indicator light illuminated.

|

LCD is okay.

|

|

|

Other than stated above.

|

Replace instrument cluster.

|

|||

Check code 31

|

Check code 31 |

Key reminder on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Turn the headlight switch to the TNS position.

Remove key from steering lock and then insert key into steering lock after selecting check code 31. (Key reminder switch on.)

|

|

Go to next step.

|

|

|

Measure voltage at instrument cluster terminal 2B.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, replace following parts.

|

|||

|

2

|

Remove key from steering lock. (Key reminder switch off.)

|

|

Measure voltage at instrument cluster terminal 2B.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 33

|

Check code 33 |

Turn/hazard signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Turn the headlight switch to the TNS position.

Trun the hazard warning switch to on.

|

|

Go to next step.

|

|

|

Measure voltage at instrument cluster terminal 2N.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, replace following parts.

|

|||

|

2

|

Trun hazard warning switch off.

|

|

Input signal to instrument cluster is okay.

|

|

|

Measure voltage at instrument cluster terminal 2N.

Is voltage below 1.0 v?

• If as specified, replace instrument cluster.

• If not as specified, replace following parts.

|

|||

Check code 55

|

Check code 55 |

Dimmer cancel switch on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Turn the panel light control switch to the dimmer cancel position after selecting check code 55.

|

|

Go to next step.

|

|

|

Measure voltage at instrument cluster terminal 2A.

Is voltage 4 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|||

|

2

|

Turn the panel light control switch to the other position.

|

|

Measure voltage at instrument cluster terminal 2A.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 58

|

Check code 58 |

Buckle switch (passenger-side) on/off signal |

|||

|---|---|---|---|---|

|

||||

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

1

|

Seat one person in the passenger’s seat, and unfasten passenger-side seat belt. (Occupancy sensor and buckle switch ON)

|

|

Go to next step.

|

|

|

Measure voltage at instrument cluster terminal 1A.

Is voltage 0 V?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|||

|

2

|

Seat one person in the passenger’s seat, and fasten passenger-side seat belt. (Occupancy sensor ON and buckle switch OFF)

Seat no person in the passenger’s seat, and unfasten passenger-side seat belt. (Occupancy sensor OFF and buckle switch ON)

Seat no person in the passenger’s seat, and fasten passenger-side seat belt. (Occupancy sensor and buckle switch OFF)

|

|

Measure voltage at instrument cluster terminal 1A.

Is voltage B+?

• If as specified, replace instrument cluster.

• If not as specified, inspect following parts.

|

|

|

Input signal to instrument cluster is okay.

|

|||

Check code 59

Diagnostic procedure

|

STEP |

INSPECTION |

INDICATION |

ACTION |

|

|---|---|---|---|---|

|

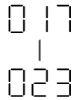

1

|

The three digits number is indicated after selecting check code 59. Confirm the first digit from the right.

|

|

The CAN system is okay.

Go to next step.

|

|

|

The DTC of CAN system is detected.

Perform the DTC inspection. (See DTC TABLE [MULTIPLEX COMMUNICATION SYSTEM])

• If the CAN system is okay, replace the instrument cluster.

Go to next step.

|

|||

|

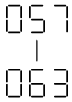

2

|

Confirm the second digit from the right.

|

|

The wiring harnesses between the fuel gauge sender unit and instrument cluster are okay.

Go to next step.

|

|

|

Inspect following parts.

• Fuel gauge sender unit

• Wiring harness (Fuel gauge sender unit—instrument cluster)

Go to next step.

|

|||

|

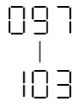

3

|

Confirm the third digit from the right.

|

|

The fuel pulse signal from the PCM is okay.

|

|

|

Inspect the PCM.

(See DTC TABLE [L8, LF, L3].)

(See DTC TABLE [MZR-CD (RF Turbo)].))

(See PCM INSPECTION [L8, LF, L3].)

• If the PCM is okay, replace the instrument cluster.

|

|||