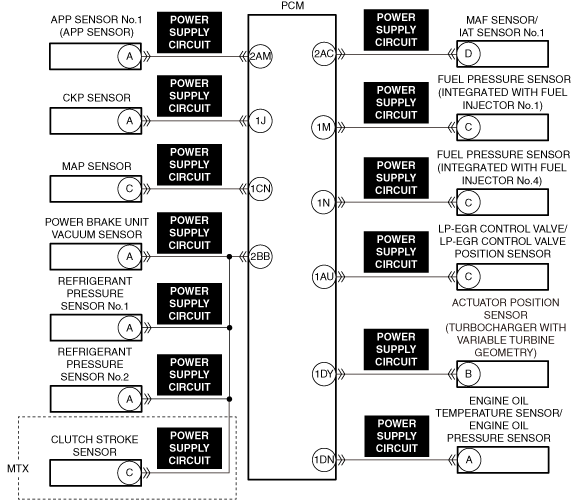

System malfunction location

Constant voltage power supply circuit low input

Detection condition

• When the following condition is met, the output voltage of the constant voltage (5 V) power supply terminal is less than 2.36 V for a continuous 0.5 s.

-

― Battery positive voltage: 8—16 V

Fail-safe

• PCM restricts engine torque.

• Limits the maximum engine speed.

• Inhibits the DENOx/DESOx control.

• Inhibits the diesel particulate filter regeneration control.

• Inhibits the EGR control.

• PCM restricts engine-transaxle integration control. (ATX)

• Inhibits engine-stop by operating the i-stop function.

Possible cause

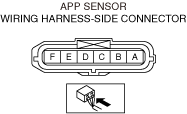

• APP sensor connector or terminal malfunction

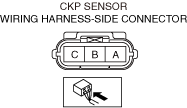

• CKP sensor connector or terminal malfunction

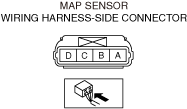

• MAP sensor connector or terminal malfunction

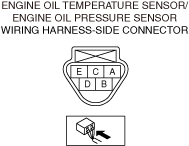

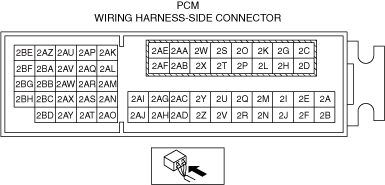

• Engine oil temperature/engine oil pressure sensor connector or terminal malfunction

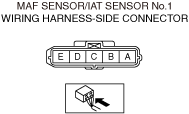

• MAF/IAT sensor No.1 connector or terminal malfunction

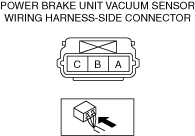

• Power brake unit vacuum sensor connector or terminal malfunction

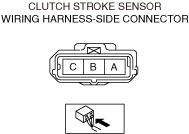

• Clutch stroke sensor connector or terminal malfunction (MTX)

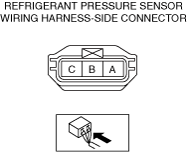

• Refrigerant pressure sensor No.1 connector or terminal malfunction

• Refrigerant pressure sensor No.2 connector or terminal malfunction

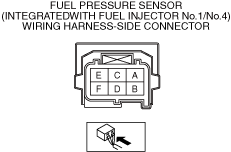

• Fuel pressure sensor (integrated with fuel injector No.1) connector or terminal malfunction

• Fuel pressure sensor (integrated with fuel injector No.4) connector or terminal malfunction

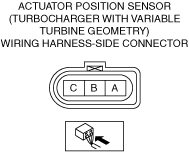

• Actuator position sensor (turbocharger) connector or terminal malfunction

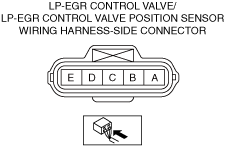

• LP-EGR control valve/LP-EGR control valve position sensor connector or terminal malfunction

• Short to ground in APP sensor power supply circuit

• Short to ground in CKP sensor power supply circuit

• Short to ground in MAP sensor power supply circuit

• Short to ground in engine oil temperature/engine oil pressure sensor power supply circuit

• Short to ground in MAF/IAT sensor No.1 power supply circuit

• Short to ground in Power brake unit vacuum sensor power supply circuit

• Short to ground in Clutch stroke sensor power supply circuit

• Short to ground in Refrigerant pressure sensor No.1 power supply circuit

• Short to ground in Refrigerant pressure sensor No.2 power supply circuit

• Short to ground in Fuel pressure sensor (integrated with fuel injector No.1) power supply circuit

• Short to ground in Fuel pressure sensor (integrated with fuel injector No.4) power supply circuit

• Short to ground in Actuator position sensor (turbocharger) power supply circuit

• Short to ground in LP-EGR control valve power supply circuit

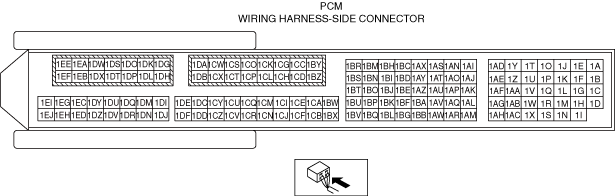

• PCM connector or terminal malfunction

• PCM malfunction