FUEL PUMP UNIT INSPECTION [L8, LF, L3]

FUEL PUMP UNIT INSPECTION [L8, LF, L3]

id0114b1801100

-

Caution

-

• It is normal to hear the fuel pump operating when the ignition switch is turned to the ON position.

-

Note

-

• To improve startability, the fuel pump control operates the fuel pump unit when the ignition switch is turned to the ON position. Due to this, fuel pressure is rapidly increased and fuel control is stabilized.

Continuity Inspection

-

Note

-

• Perform the following inspection only when directed.

1. Disconnect the negative battery cable.

2. Remove the service hole cover. (See FUEL PUMP UNIT REMOVAL/INSTALLATION [L8, LF, L3 2WD].) (See FUEL PUMP UNIT REMOVAL/INSTALLATION [L3 4WD].)

3. Disconnect the fuel pump unit connector.

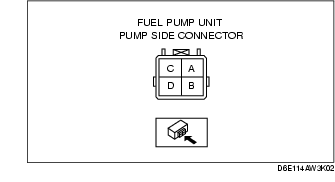

4. Inspect for continuity between fuel pump unit connector terminals B and D.

-

• If there is no continuity, replace the fuel pump body.

-

• If as specified carry out the "Circuit Open/Short Inspection".

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for open or short circuit (continuity check).

Open circuit

-

• If there is no continuity, the circuit is open. Repair or replace the harness.

-

- Fuel pump unit terminal D (harness-side) and body GND.

-

- Fuel pump relay terminal D (harness-side) and fuel pump unit terminal B (harness-side).

Short circuit

-

• If there is continuity, the circuit is short. Repair or replace the harness.

-

- Fuel pump unit terminal D (harness-side) and power supply.

-

- Fuel pump unit terminal B (harness-side) and body GND.

Fuel Pump Hold Pressure Inspection

-

Warning

-

• Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Always carry out the following procedure with the engine stopped.

-

Caution

-

• Disconnecting/connecting the quick release connector without cleaning it may possibly cause damage to the fuel pipe and quick release connector. Always clean the quick release connector joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is free of foreign material.

-

Note

-

• Perform the following test only when directed.

1. Complete the "BEFORE REPAIR PROCEDURE". (See BEFORE REPAIR PROCEDURE [L8, LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the air cleaner.

-

Caution

-

• The quick release connector may be damaged if the tab is turned too far. Do not turn the tab over the stopper.

4. Disconnect the quick release connector from the fuel tank as follows:

-

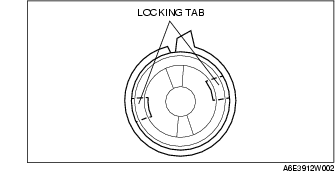

(1) Push the tab on the locking coupler 90° until it stops.

-

(2) Pull the fuel hose straight back.

-

Note

-

• The stopper may be removed from the quick connector. Take care not to loose it.

-

Reinstall it to the quick release connector before reconnecting the fuel line.

-

• The locking coupler has two internal locking tabs which retain the pulsation damper pipe. Be sure that the tab on the locking coupler is rotated until it stops to release two internal locking tabs.

5. Cover the disconnected quick release connector with vinyl sheet or the like to prevent it from being scratched or contaminated with foreign material.

6. Turn the lever 90 degrees against the hose of the SST to plug the SST outlet.

7. Push the SST quick release connector into the fuel pipe until a click is heard.

8. Set the fuel hose into a container to avoid fuel spills.

9. Connect the negative battery cable.

-

Caution

-

• Connecting to the wrong check connector terminal may possibly cause malfunction. Carefully connect to the specified terminal only.

10. Short the check connector terminal F/P to body GND using a jumper wire.

11. Turn the ignition switch to ON to operate the fuel pump.

12. Turn the ignition switch to LOCK position.

13. Measure the fuel pump hold pressure after 5 minutes.

-

• If not as specified, replace the fuel pump after inspecting the following:

-

- Fuel line for clogging or leakage

Fuel pump hold pressure

-

More than 200 kPa {2.0 kgf/cm2, 29 psi}

14. Disconnect the jumper wire.

15. Disconnect the SST.

-

Note

-

• A checker tab is integrated with the quick release connector for new plastic fuel hoses. The checker tab will be released from the quick release connector after it is completely engaged with the fuel pipe.

16. Inspect the plastic fuel hose and fuel pipe sealing surface for damage and deformation, and replace as necessary.

-

• If the quick release connector O-ring is damaged or has slipped, replace the plastic fuel hose.

17. Apply a small amount of clean engine oil to the sealing surface of the fuel pipe.

18. Reconnect the plastic fuel hose straight to the fuel pipe until a click is heard.

19. Lightly pull and push the quick release connector a few times by hand and verify that it can move 2.0-3.0 mm {0.08-0.11 in} and it is connected securely.

-

• If quick release connector does not move at all, verify that O-ring is not damaged and slipped, and reconnect the quick release connector.

20. Complete the "AFTER REPAIR PROCEDURE". (See AFTER REPAIR PROCEDURE [L8, LF, L3].)