1. Apply the parking brake and use wheel chocks at the front and rear of the wheels.

2. Inspect the engine coolant. (See ENGINE COOLANT LEVEL INSPECTION [L8, LF, L3, L3 Turbo].)

3. Inspect the engine oil. (See ENGINE OIL LEVEL INSPECTION [L8, LF, L3].)

4. Inspect the ATF levels. (See Automatic Transaxle Fluid (ATF) Level Inspection.)

5. Inspect the idle speed and ignition timing in P position. (See Idle Speed Inspection.) (See Ignition Timing Inspection.)

Note

• Line pressure cannot be measured on the JA5AX-EL automatic transaxle. Measure the low clutch pressure in place of D and M range line pressures. Measure the reverse clutch pressure in place of R position line pressure.

1. Engine idling.

(1) Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

Warning

• Removing the plug when the ATF is hot can be dangerous. Hot ATF can come out of the opening and badly burn you. Before removing the square-head plug, allow the ATF to cool.

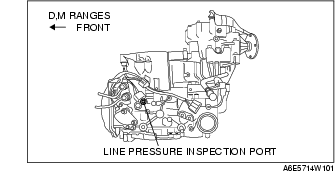

(2) Remove the plug and O-ring shown in the figure.

(3) Connect the SSTs (49 L019 014, 49 B019 901B, and 49 0378 400C) to the low clutch pressure inspection port (D and M range line pressures) or reverse clutch pressure inspection port (R position line pressure).

(4) Start the engine and warm it up until the ATF reaches 60-70 °C {140-158 °F}.

(5) Shift the selector lever to D range.

(6) Read the line pressure at idle for the remaining ranges in the same manner.

• M range (1GR, 2GR)

• R range

ATF temperature

60-70 °C {140-158 °F}

Turn off all electrical loads

Line pressure (idle)

D, M (2GR) range: 290-490 kPa {3.0-5.0 kgf/cm2, 42-71 psi}

M (1GR) range, R position: 550-750 kPa {5.6-7.6 kgf/cm2, 80-109 psi}}

(7) Turn the engine off.

2. Engine stall speed.

(1) Replace the SST (49 B019 901B) with the gauge of the SST (49 0378 400C).

(2) Start the engine.

Caution

• Do not maintain WOT in any gear range for more than 5 s or transaxle damage will occur.

(3) Firmly depress the brake pedal with the left foot, and then gradually depress the accelerator pedal to the floor (WOT) with the right.

(4) When the engine speed no longer increases, quickly read the line pressure and release the accelerator pedal.

(5) Shift the selector lever to N position and let the engine idle for 1 minute or more to cool the ATF.

(6) Read the line pressure at the engine stall speed for the remaining ranges in the same manner.

• M range (1GR, 2GR)

• R range

ATF temperature

60-70 °C {140-158 °F}

Turn off all electrical loads

Line pressure (stall)

D, M (1GR, 2GR) range, R position: 1,550-1,750 kPa {15.8-17.8 kgf/cm2, 225-254 psi}

(7) Shift the selector lever to P position.

(8) Turn off the engine.

(9) Remove the SSTs and install a new square head plug and O-ring in the line pressure inspection port.

Tightening torque

4.91-9.80 N·m {50-100 kgf·cm, 43.4-86.7 in·lbf}

Evaluation of line pressure test

1. Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

2. Connect a tachometer.

3. Start the engine.

4. Shift the selector lever to D range.

5. Firmly depress the brake pedal with the left foot, and gently depress the accelerator pedal to the floor (WOT) with the right.

6. When the engine speed no longer increases, quickly read the engine speed and release the accelerator pedal.

7. Shift the selector the to N position and let the engine idle for 1 minute or more to cool the ATF.

8. Perform stall tests for the remaining ranges and position in the same manner.

ATF temperature

60-70 °C {140-158 °F}

Turn off all electrical loads

Engine stall speed

2,200-2,600 rpm

9. Turn off the engine.

Evaluation of stall test

1. Perform mechanical system test preparation. (See Mechanical System Test Preparation.)

2. Start the engine.

3. Warm up the engine until the ATF temperature reaches 60-70°C {140-158°F}. Shift the selector lever from N position to D range.

4. Use a stopwatch to measure the time it takes from shifting until engagement is felt. Take three measurements for each test and average the results using the following formula.

Formula

Average time lag = (Time 1 + Time 2 + Time 3) / 3

5. Perform the test for the following shifts in the same manner.

Time lag

N → D range... approx. 0.5-1.0 s

N → R position... approx. 0.6- 1.0 s

Evaluation of time lag test