|

ELECTRIC AT OIL PUMP REMOVAL/INSTALLATION [ET6A-EL, ET6AX-EL]

id0517n3117600

Replacement Part

|

O-ring

Quantity: 2

Location of use: Electric AT oil pump

|

Oil and Chemical Type

|

sealant

Type: TB1217E or equivalent

|

1. Turn the steering wheel left until it locks.

2. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION [(E)].)

3. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

4. Remove the front splash shield (LH). (See SPLASH SHIELD REMOVAL/INSTALLATION.)

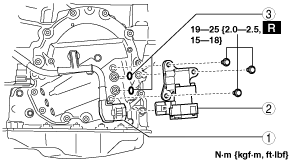

5. Remove in the order indicated in the table.

am3zzw00012649

|

|

1

|

Electric AT oil pump connector

|

|

2

|

Electric AT oil pump

|

|

3

|

O-ring

|

6. Install in the reverse order of removal.

7. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT [ET6A-EL, ET6AX-EL (E)].)

8. Bleed air using the following procedure.

9. Adjust the ATF level. (See AUTOMATIC TRANSAXLE FLUID (ATF) ADJUSTMENT [ET6A-EL, ET6AX-EL (E)].)

Electric AT Oil Pump Installation Note

1. Apply a light coat of silicon sealant (TB1217E or equivalent) to the contact surfaces of the electric AT oil pump and end cover.

am6zzw00017737

|

2. Install the electric AT oil pump before the applied sealant starts to harden.