|

1

|

VERIFY BODY CONTROL MODULE (BCM) DTCs

• Perform the DTC inspection for the body control module (BCM) using the M-MDS.

• Is a DTC detected?

|

Yes

|

Perform the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

2

|

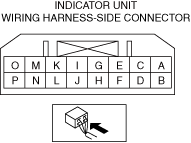

INSPECT INDICATOR UNIT CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the negative battery terminal.

• Disconnect the indicator unit connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is there any malfunction of the indicator unit connector?

|

Yes

|

Replace the malfunctioning part and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

3

|

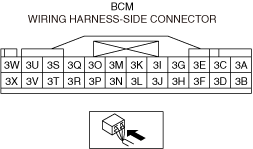

INSPECT BODY CONTROL MODULE (BCM) CONNECTOR CONDITION

• Disconnect the body control module (BCM) connector.

• Inspect the connector engagement and connection condition and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the malfunctioning part and perform the repair completion verification.

|

|

4

|

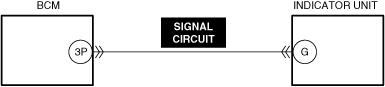

INSPECT INDICATOR UNIT SIGNAL CIRCUIT FOR SHORT TO GROUND

• Indicator unit and body control module (BCM) connectors are disconnected.

• Inspect the PAD OFF indicator circuit for short to ground.

-

Note

-

• Inspect for a short to ground while shaking the wiring harness between the indicator unit and body control module (BCM).

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT INDICATOR UNIT SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Indicator unit and body control module (BCM) connectors are disconnected.

• Inspect the PAD OFF indicator circuit for open circuit.

-

Note

-

• Inspect for open circuit while shaking the wiring harness between the indicator unit and body control module (BCM).

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT INDICATOR UNIT SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Indicator unit and body control module (BCM) connectors are disconnected.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Inspect the PAD OFF indicator circuit for a short to power supply.

-

Note

-

• Inspect for a short to power supply while shaking the wiring harness between the indicator unit and body control module (BCM).

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT INDICATOR UNIT

• Inspect the indicator unit.

• Is the part normal?

|

Yes

|

Perform the repair completion verification.

|

|

No

|

Replace the indicator unit and perform the repair completion verification.

|

|

Repair completion verification

|

PERFORM SAS CONTROL MODULE DTC INSPECTION

• Reconnect all disconnected connectors.

• Connect the negative battery terminal.

• Switch the ignition ON (engine off or on).

• Clear the DTC for the SAS control module using the M-MDS.

• Perform the DTC inspection for the SAS control module using the M-MDS.

• Are the same Pending DTCs present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the SAS control module.

|

|

No

|

DTC troubleshooting completed.

|