|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

|

—

|

Go to the next step.

|

|

2

|

VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

|

Yes

|

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT FOR OTHER RELATED DTCs

• Perform the DTC inspection for the PCM.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

4

|

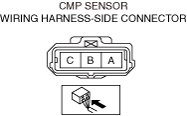

INSPECT CMP SENSOR CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

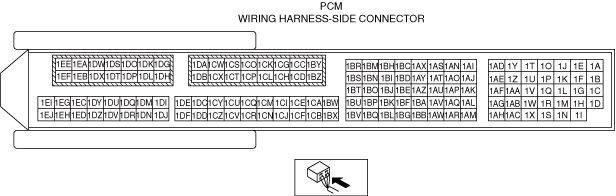

INSPECT PCM CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

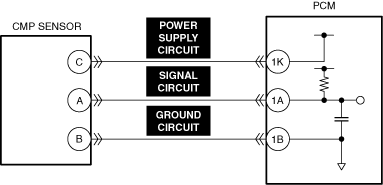

INSPECT CMP SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT CMP SENSOR SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT CMP SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT AND GROUND CIRCUIT FOR SHORT CIRCUIT

• Inspect the applicable circuits for a short circuit.

• Is the circuit normal?

|

Yes

|

Go to repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT CMP SENSOR POWER SUPPLY CIRCUIT AND SIGNAL CIRCUIT AND GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT CMP SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT CKP SENSOR CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal.

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

INSPECT CKP SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

13

|

VERIFY ASSEMBLY CONDITION OF TIMING CHAIN

• Verify the condition of the timing chain assembly (valve timing, looseness, jumping).

• Is the timing chain condition normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location.

Assemble the timing chain using the correct timing, then go to the next step.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

-

― Perform the KOER self-test.

• Perform the DTC inspection for the PCM.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|