Description

• P0396:00: Cylinder pressure sensor No.1: Function malfunction

• P03A0:00: Cylinder pressure sensor No.2: Function malfunction

• P03AA:00: Cylinder pressure sensor No.3: Function malfunction

• P03B4:00: Cylinder pressure sensor No.4: Function malfunction

Detection condition

Determination conditions

• If any of the following conditions is met:

-

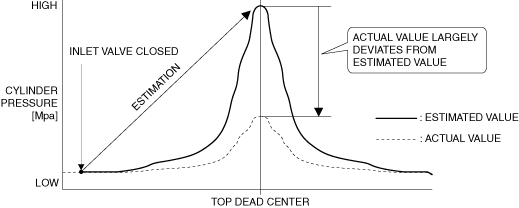

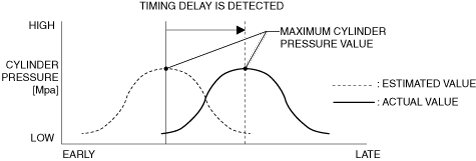

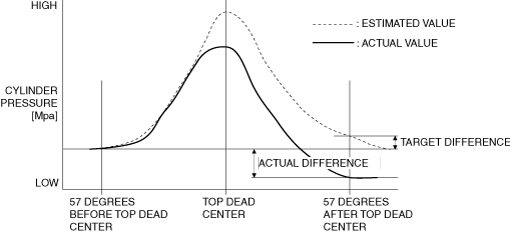

― Actual cylinder pressure value is higher or lower than estimated cylinder pressure value― Timing at which cylinder pressure reaches maximum value is later than target value― Actual cylinder pressure difference before and after top dead center is larger than target value

Preconditions

• Battery voltage: 9—18 V*1

• Engine speed: 1,000—3,000 rpm or less*1

• Charging efficiency: 0.35 or less

• Engine coolant temperature: −8 °C {18 °F} or more*1

• Fuel-cut control is being performed

• EGR valve: Fully close*1

• Purge control inhibited

• Not cranking

• Not stalling

• Output value of cylinder pressure sensor is normal

• Output value of CKP sensor is normal

• Output value of CMP sensor is normal

• Output value of MAP sensor is normal

• Closing angle (ATDC) of intake valve is within specified value

• The following DTCs are not detected:

-

― MAP sensor: P0106:00, P0107:00 or P0108:00― Intake electric variable valve timing circuit: P0010:00 or P1380:00― Cylinder pressure sensor No.1: P0397:00 or P0398:00― Cylinder pressure sensor No.2: P03A1:00 or P03A2:00― Cylinder pressure sensor No.3: P03AB:00 or P03AC:00― Cylinder pressure sensor No.4: P03B5:00 or P03B6:00― ETC sensor: P0116:00, P0117:00 or P0118:00― EGR valve: P0403:00― EGR valve position sensor: P0405:00 or P0406:00― Purge solenoid valve: P0443:00

*1: Standard can be verified by displaying PIDs using M-MDS

Drive cycle

• 1

Self test type

• CMDTC self test

Sensor used

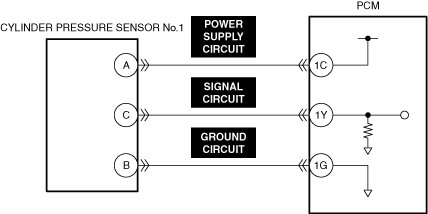

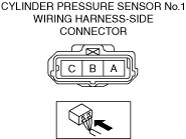

• Cylinder pressure sensor No.1

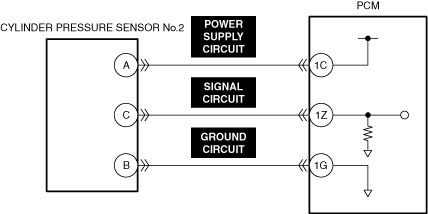

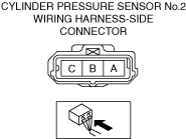

• Cylinder pressure sensor No.2

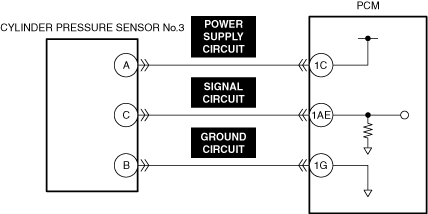

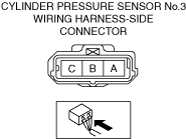

• Cylinder pressure sensor No.3

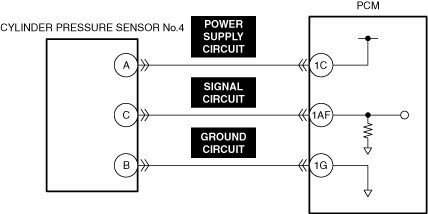

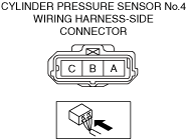

• Cylinder pressure sensor No.4

• MAP sensor

• CKP sensor

• CMP sensor

Fail-safe function

• Inhibits the EGR control.

• Inhibits the SPCCI control.

• Stops the combustion control feedback.

• Retards the ignition timing.

Vehicle status when DTCs are output

• Not applicable

Possible cause

• Cylinder pressure sensor connectors or terminals malfunction

• PCM connector or terminals malfunction

• Short to ground in any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit

• Short to power supply in cylinder pressure sensor signal circuit

• Short circuit between any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit― Ground circuit

• Open circuit in any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit― Ground circuit

• Cylinder pressure sensor malfunction

• Incorrect fuel injection timing

• Fuel injector malfunction

• Insufficient engine compression

• PCM malfunction