DTC P250F:00 [PCM (SKYACTIV-D)]

Home

Note

• To determine the malfunctioning part, proceed with the diagnostics from [Function inspection using M-MDS].

Description

Engine oil system: Engine oil level is too low

Detection condition

Determination condition

• Engine oil level is near or below L mark on oil level gauge

Preconditions

• Engine speed: 750—3,000 rpm

• Vehicle speed: 5 km/h {3 mph} or more

• Hydraulic control: During low hydraulic pressure

• Oil temperature: 20—120 °C {68—248 °F}

• Acceleration of vehicle in the forward/rearward and left/right directions: 0.2 G or less

• The following DTCs are not detected

― LIN communication: U1100:00

― Engine oil temperature sensor: P0196:00, P0197:00, P0198:00

― Engine oil level sensor: P250C:00

Drive cycle

• 1

Self-test type

• CMDTC self test

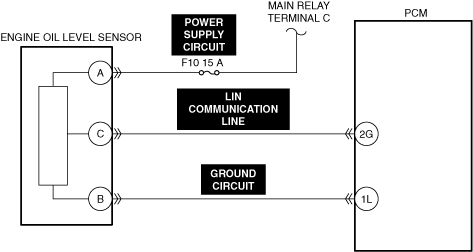

Sensor/unit used

• PCM

• Engine oil level sensor

• Engine oil temperature sensor

• Low-G sensor

Fail-safe

• Not applicable

Vehicle status when dtcs are output

• Engine oil level warning indication/engine oil level warning light

Possible cause

• Insufficient engine oil

• Engine oil leakage

• Engine oil level sensor malfunction

― Oil passage clogging

― Integrated circuit in engine oil level sensor malfunction

• Signal error to PCM

― Engine oil level sensor connector or terminal malfunction

― Open circuit in engine oil level sensor LIN communication line

• PCM malfunction

• The PCM monitors the oil level received from the engine oil level sensor, and the oil level average value is calculated at 10 min or more intervals or when the distance traveled is 100 km {62.1 mile} or more .

• If the PCM determines that the oil level average value is at the position -2 mm {-0.08 in} from the L mark on the oil level gauge 3 times consecutively, the PCM stores DTCs and displays the engine oil level warning indication/engine oil level warning light.

• After the engine oil level warning indication/engine oil level warning light initially turn on and the ignition is switched OFF, the engine oil level warning indication/engine oil level warning light turn off. After this, when the ignition is switched ON (engine off), the PCM turns on the engine oil level warning indication/engine oil level warning light if it determines that the oil level is low again.

1. Park the vehicle on a flat surface and switch the ignition ON (engine off).

2. Verify that the engine oil level is near the X mark on the oil level gauge.

PID

Item name

Reference

ENG_OIL_LVL

Step

Inspection

Results

Action

1

PURPOSE: VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

Yes

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

2

PURPOSE: IDENTIFY TRIGGER DTC FOR FREEZE FRAME DATA

• Is DTC P250F:00 causing the freeze frame data?

Yes

Go to the next step.

No

Go to the troubleshooting procedure for DTC on freeze frame data.

3

PURPOSE: RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

Note

• Recording can be facilitated using the screen capture function of the PC.

—

Go to the next step.

4

PURPOSE: VERIFY OTHER RELATED DTCs

• Perform the DTC inspection for the PCM.

• Are any other DTCs displayed?

Yes

Repair the malfunctioning location according to the applicable DTC troubleshooting.

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

No

Go to the next step.

5

PURPOSE: VERIFY PID AS TO WHETHER MALFUNCTION IS CAUSED BY INPUT SIGNAL TO PCM

• Display PID ENG_OIL_LVL using the M-MDS.

• Are the monitoring values normal?

Yes

Go to the next step.

No

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

6

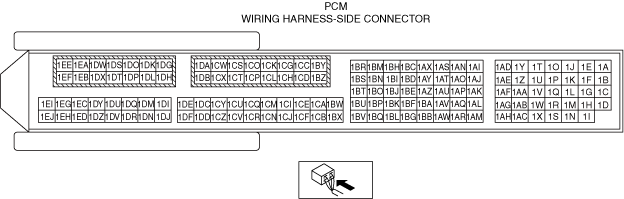

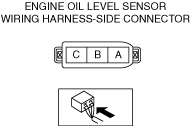

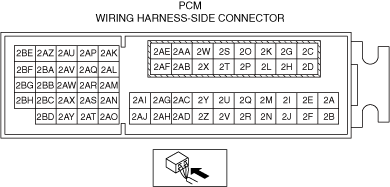

PURPOSE: VERIFY CONNECTOR CONNECTION CONDITION

• Display PID ENG_OIL_LVL using the M-MDS.

• Does the PID value fluctuate when a new connector is shaken?

― Engine oil level sensor

― PCM

Yes

Repair or replace the applicable wiring harness or connector parts.

Go to the troubleshooting procedure to perform the procedure from repair completion verification.

No

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

Intention of troubleshooting procedure

• Step 1

― Verify engine oil level.

• Step 2

― Inspect oil passage for clogging.

• Repair completion verification

― Verify that the primary malfunction is resolved and there are no other malfunctions.

Step

Inspection

Results

Action

1

PURPOSE: INSPECT ENGINE OIL LEVEL

• Inspect the engine oil level.

• Is the engine oil level sufficient?

Yes

Replace the engine oil.

Implement the engine oil data reset procedure.

Go to repair completion verification.

No

Go to the next step.

2

PURPOSE: INSPECT OIL PASSAGE FOR CLOGGING

• Remove the engine oil level sensor.

• Inspect the hydraulic passage of the engine oil level sensor.

• Is the engine oil level sensor normal?

Yes

Replace the engine oil level sensor, then go to the next step.

No

Clean the engine oil level sensor, then go to the next step.

Repair completion verification 1

PURPOSE: VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

― Implement the repeatability verification procedure.

• Perform the DTC inspection for the PCM.

• Is the same Pending DTC present?

Yes

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

No

Go to the next step.

Repair completion verification 2

PURPOSE: VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any other DTCs displayed?

Yes

Repair the malfunctioning location according to the applicable DTC troubleshooting.

No

DTC troubleshooting completed.