Description

Swirl control circuit range/performance problem

Detection condition

Determination conditions

• The actual opening angle of the swirl control valve is larger or smaller than its target opening angle for the specified time.

Preconditions

• Battery voltage: above 11 V*1

• Engine coolant temperature: 20 °C {68 °F} or more*1

• The following DTCs are not detected:

-

― P2008:00, P2016:00 and P2017:00

*1: Standard can be verified by displaying PIDs using M-MDS

Drive cycle

• 1

Self test type

• CMDTC self test, KOEO self test, KOER self test

Sensor used

• Swirl control valve position sensor

Fail-safe function

• Limits intake air amount

• Stops the EGR control.

Vehicle status when DTCs are output

• Not applicable

Possible cause

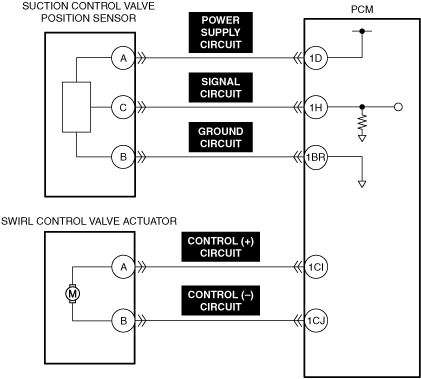

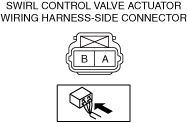

• Swirl control valve actuator connector or terminals malfunction

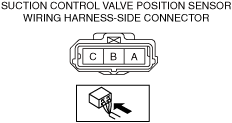

• Swirl control valve position sensor connector or terminals malfunction

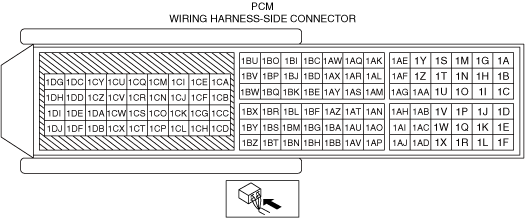

• PCM connector or terminals malfunction

• Short to ground in swirl control valve actuator control circuit

• Short to power supply in swirl control valve actuator control circuit

• Open circuit in swirl control valve actuator control circuit

• Short to ground in any of the following swirl control valve position sensor circuits.

-

― Power supply circuit― Signal circuit

• Short to power supply in any of the following swirl control valve position sensor circuits.

-

― Signal circuit― Ground circuit

• Open circuit in any of the following swirl control valve position sensor circuits.

-

― Power supply circuit― Signal circuit― Ground circuit

• Swirl control valve actuator malfunction

• Swirl control valve position sensor malfunction

• PCM malfunction