|

1

|

INSPECT BRAKE FLUID LEVEL

• Inspect the brake fluid level.

• Is the brake fluid level normal?

|

Yes

|

Go to the next step.

|

|

No

|

Add genuine brake fluid and go to the next step.

|

|

2

|

INSPECT BRAKE PIPE AND BRAKE HOSE FOR BRAKE FLUID LEAKAGE

• Perform the brake fluid leakage inspection for the brake pipe and brake hose.

• Is there brake fluid leakage?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT ELECTRONICALLY CONTROLLED BRAKE UNIT FOR BRAKE FLUID LEAKAGE

• Remove the brake pedal and inspect the electronically controlled brake unit for brake fluid leakage.

• Is there brake fluid leakage?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification 2.

|

|

No

|

Go to the next step.

|

|

4

|

VERIFY IF AIR IS TRAPPED IN BRAKE LINE

• Select the following items from the initialization screen of the M-MDS.

-

1. “Toolbox”

2. “Work Support”

3. “BRAKES”

4. “Self-Diagnosing Brake Line”

• Perform the Self-Diagnosing Brake Line according to the directions on the screen.

• Is the result normal?

|

Yes

|

Go to the next step.

|

|

No

|

Bleed the air from the brake fluid according to the diagnostic result, and go to the repair completion verification.

|

|

5

|

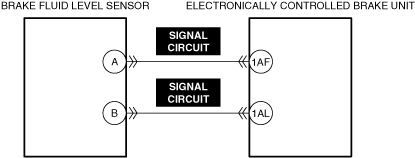

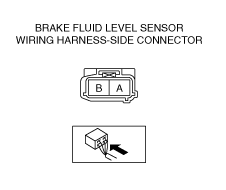

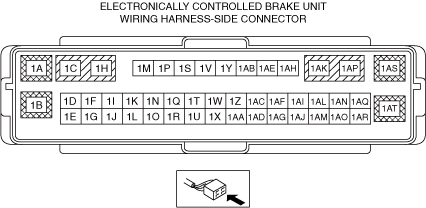

INSPECT BRAKE FLUID LEVEL SENSOR SIGNAL CIRCUITS FOR SHORT CIRCUIT

• Inspect the applicable circuits for short circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT BRAKE FLUID LEVEL SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

• Perform the work of depressing the brake pedal for 3 s or more and then releasing it for 5 times or more with the ignition switched ON (engine off or on).

• Perform the DTC inspection for the electronically controlled brake unit.

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the electronically controlled brake unit, then go to the next step.

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|