|

am2zzw00012621

DTC P049C:00 [PCM (SKYACTIV-D)]

id0102t5856500

Details On DTCs

|

Description |

LP-EGR flow excessive detected |

|

|---|---|---|

|

Detection condition

|

Determination conditions

|

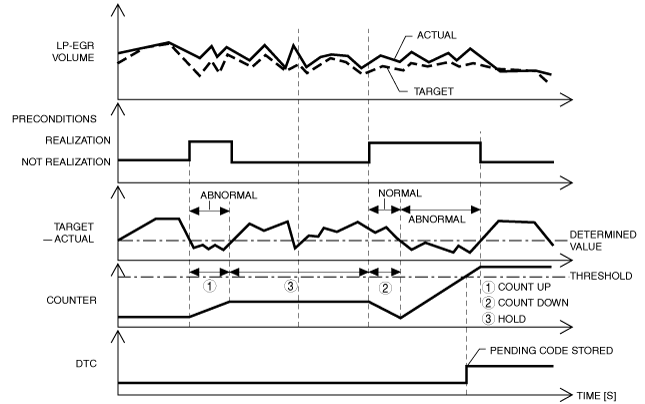

• When the following condition is met, the LP-EGR volume is higher than the specification for -0.30 g/rev for a continuous 8.2 s.

|

|

Preconditions

|

• During LP-EGR control

• During HP-EGR control

• Fuel injection amount:15—50 mm3/stoke

• Engine speed: 1,300—6,000 rpm

• Engine torque: 70—240 N·m{7.2—24 kgf·m, 52—177 ft·lb}

• Target HP-EGR flow volume: 0.31―0.6 g/rev

• The following DTCs are not detected:

|

|

|

Drive cycle

|

• 1

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• LP-EGR control valve

• HP-EGR control valve

• Intake shutter valve

• Exhaust shutter valve

• MAF sensor

• MAP sensor

• Boost air temperature sensor

• Exhaust gas pressure sensor No.1

• Exhaust gas temperature sensor No.1 etc.

|

|

|

Fail-safe

|

• Not applicable

|

|

|

Vehicle status when dtcs are output

|

• Check engine light is illuminated

|

|

|

Possible cause

|

• Erratic signal to PCM

• HP-EGR system malfunction

• Exhaust shutter valve malfunction

• LP-EGR control valve malfunction (stuck close)

• Exhaust shutter valve position sensor (built-into exhaust shutter valve) malfunction

• LP-EGR control valve position sensor (built-into LP-EGR control valve) malfunction

• EGR cooler clogged

• Exhaust gas leakage from LP-EGR system

• LP-EGR system passage malfunction (restriction)

• Air suction in intake air system between turbocharger and intake manifold

• PCM malfunction

|

|

System Wiring Diagram

Function Explanation (DTC Detection Outline)

am2zzw00012621

|

Repeatability Verification Procedure

PID Item/Simulation Item Used In Diagnosis

PID/DATA monitor item table

|

Item (definition) |

Reference |

|---|---|

|

CHARGE_AIR_COOL_TEMP

|

|

|

EX_PRES

|

|

|

EX_GAS_TEMP_1

|

|

|

MAP

|

|

|

MAF

|

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED REPAIR INFORMATION OR SERVICE INFORMATION AVAILABILITY

• Verify related Service Bulletins, on-line repair information, or Service Information availability.

• Is any related Information available?

|

Yes

|

Perform repair or diagnosis according to the available information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: VERIFY DTC CAUSING FREEZE FRAME DATA

• Is DTC P049C:00 causing the freeze frame data?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the DTC causing the freeze frame data.

(See DTC TABLE [PCM (SKYACTIV-D)].)

|

||

|

3

|

PURPOSE: RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snapshot data.

|

—

|

Go to the next step.

|

|

4

|

PURPOSE: VERIFY OTHER RELATED DTCs

• Perform the DTC inspection for the PCM.

(See DTC INSPECTION)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

(See DTC TABLE [PCM (SKYACTIV-D)].)

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: VERIFY IF THERE IS PID ITEM CAUSING DRASTIC CHANGES OF ACCELERATION FLUCTUATION BY INPUT SIGNAL TO PCM

• Access the following PIDs using the M-MDS:

(See DTC INSPECTION.)

PCM:

• Is there any signal that is far out of specification?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

||

|

6

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Access the following PIDs using the M-MDS:

(See DTC INSPECTION.)

PCM:

• When the following parts are shaken, does the PID value include a PID item which has changed?

|

Yes

|

Repair or replace the applicable connector parts.

Go to the troubleshooting procedure to perform the procedure from repair completion verification.

|

|

No

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

Troubleshooting Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: IINSPECT EXHAUST SHUTTER VALVE POSITION SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the exhaust shutter valve, then go to repair completion verification.

|

||

|

2

|

PURPOSE: INSPECT LP-EGR CONTROL VALVE CONTROL SYSTEM OPERATION

• Perform the LP-EGR Control Valve Operation Inspection.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: INSPECT LP-EGR CONTROL VALVE POSITION SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

4

|

PURPOSE: INSPECT INTAKE AIR SYSTEM FOR AIR SUCTION

• Inspect for air leakage at the following:

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT FOR RESTRICTION OR CLOGGED IN HP-EGR PASSAGE

• Switch the ignition off.

• Remove the HP-EGR control valve.

• Visually inspect the HP-EGR passage for clogging and the gasket correctly installed.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to the next step.

(If there is clogging caused by soot in the HP-EGR control valve, inspect around the HP-EGR piping and clean or replace it.)

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: INSPECT EGR COOLER FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

||

|

7

|

PURPOSE: INSPECT LP-EGR SYSTEM FOR LEAKAGE

• Visually inspect for exhaust gas leakage from the LP-EGR system.

• Is there any leakage?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to repair completion verification.

|

|

No

|

Go to the next step.

|

||

|

8

|

PURPOSE: INSPECT FOR RESTRICTION IN LP-EGR SYSTEM PASSAGE

• Switch the ignition off.

• Remove the LP-EGR control valve.

• Visually inspect the LP-EGR passage for restriction and the gasket correctly installed.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to the next step.

(If there is restriction caused by soot in the LP-EGR control valve, inspect around the LP-EGR piping and clean or replace it.)

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 1

|

PURPOSE: VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory.

(See CLEARING DTC.)

• Replicate the vehicle conditions at the time the DTC was detected using the following procedure.

• Perform the DTC inspection for the PCM.

(See DTC INSPECTION.)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

Repair completion verification 2

|

PURPOSE: VERIFY IF OTHER DTCs DISPLAYED

• Perform the DTC inspection.

(See DTC INSPECTION.)

• Are any other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|