Description

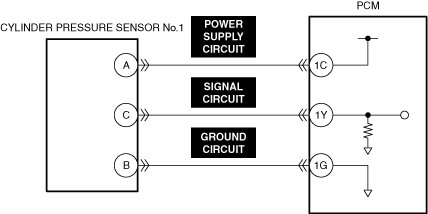

• P039E:00: Cylinder pressure sensor No.1: Abnormal combustion

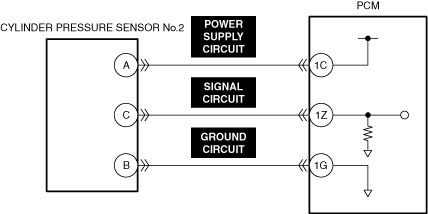

• P03A8:00: Cylinder pressure sensor No.2: Abnormal combustion

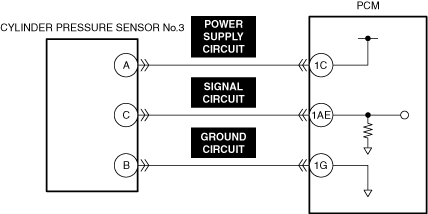

• P03B2:00: Cylinder pressure sensor No.3: Abnormal combustion

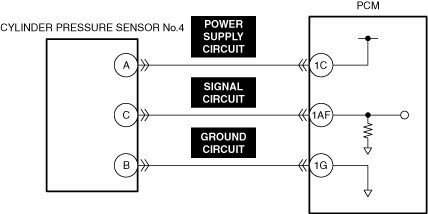

• P03BC:00: Cylinder pressure sensor No.4: Abnormal combustion

Detection condition

Determination conditions

• If any of the following conditions is met for a continuous specified period.

-

― PCM determines that detected value for combustion status is unreliable― Signal voltage input from cylinder pressure sensor to PCM is abnormal

Preconditions

• There is no misfire

• Fuel-cut control not implemented

• Vehicle is being driven within control range that allows detection of this DTC

• The following DTCs are not detected:

-

― Cylinder pressure sensor: P0396:00, P0397:00, P0398:00, P03A0:00, P03A1:00, P03A2:00, P03AA:00, P03AB:00, P03AC:00, P03B4:00, P03B5:00 or P03B6:00― CMP sensor: P0335:00― CKP sensor: P0340:00 or P0365:00

Drive cycle

• 1

Self test type

• CMDTC self test, KOER self test

Sensor used

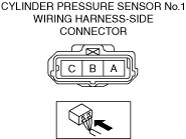

• Cylinder pressure sensor No.1

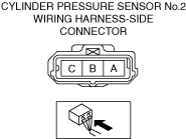

• Cylinder pressure sensor No.2

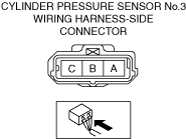

• Cylinder pressure sensor No.3

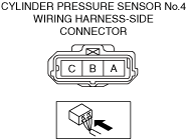

• Cylinder pressure sensor No.4

• MAP sensor

• CKP sensor

• CMP sensor

Fail-safe function

• Inhibits the EGR control.

• Inhibits the SPCCI control.

• Stops the combustion control feedback.

• Retards the ignition timing.

Vehicle status when DTCs are output

• Not applicable

Possible cause

• Cylinder pressure sensor connectors or terminals malfunction

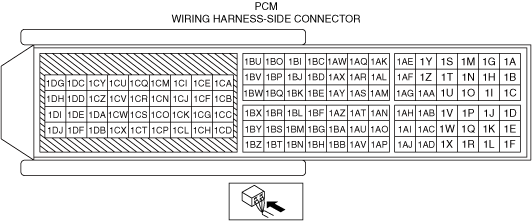

• PCM connector or terminals malfunction

• Short to ground in any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit

• Short to power supply in cylinder pressure sensor signal circuit

• Short circuit between any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit― Ground circuit

• Open circuit in any of the following cylinder pressure sensor circuits.

-

― Power supply circuit― Signal circuit― Ground circuit

• Cylinder pressure sensor malfunction

• Insufficient engine compression

• Incorrect fuel injection timing

• Fuel injector malfunction

• Poor sealing of coolant passage (leakage of engine coolant into combustion chamber)

• PCM malfunction