|

1

|

VERIFY PCM DTC

• Perform the DTC inspection for the PCM.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

2

|

VERIFY BODY CONTROL MODULE (BCM) DTC

• Perform the DTC inspection for the body control module (BCM).

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY DASH-ELECTRICAL SUPPLY UNIT DTC

• Perform the DTC inspection for the dash-electrical supply unit.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

4

|

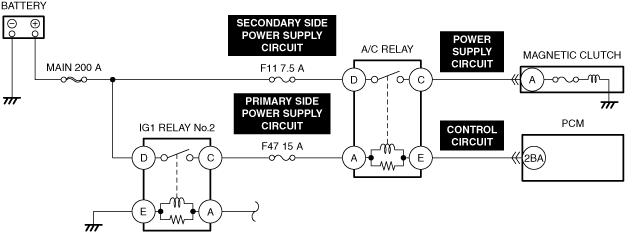

DETERMINE IF MALFUNCTION CAUSE IS A/C RELAY CONTROL SIGNAL OR A/C REQUEST SIGNAL

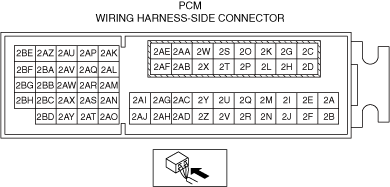

• Access the PCM simulation item A/C_RLY using the M-MDS.

• Start the engine and idle it.

• Turn the A/C_RLY PID to ON from OFF using the M-MDS simulation function.

• Is the magnetic clutch engaged?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 7.

|

|

5

|

DETERMINE IF MALFUNCTION CAUSE IS REFRIGERANT PRESSURE SENSOR OR OTHER

• Access the PCM PID A/C_REQ using the M-MDS.

• Monitor the A/C_REQ PID while turning on and off the air conditioner using the switch on the control panel.

• Is the A/C_REQ PID value normal?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 7.

|

|

6

|

INSPECT REFRIGERANT PRESSURE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Inspect the following:

• Refrigerant charging amount

• A/C compressor seized

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

DETERMINE IF MALFUNCTION CAUSE IS A/C CONTROL SIGNAL OR MAGNETIC CLUTCH

• Start the engine and idle it.

• Access the PCM simulation item A/C_SW using the M-MDS.

• Turn the A/C_SW PID to ON from OFF using the M-MDS simulation function.

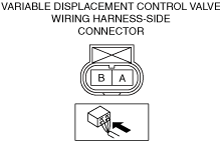

• Measure the voltage at the magnetic clutch terminal A (wiring harness-side).

• Is the voltage 10.5 V or more?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 9.

|

|

8

|

INSPECT IF MALFUNCTION CAUSE IS MAGNETIC CLUTCH OR MAGNETIC CLUTCH GROUND CIRCUIT

• Switch the ignition off.

• Disconnect the magnetic clutch connector.

• Inspect for continuity between magnetic clutch terminal A (part-side) and body ground.

• Is there continuity?

|

Yes

|

Inspect the magnetic clutch.

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Inspect the A/C compressor. (poor contact to ground)

• If there is any malfunction:

-

― Repair or replace the malfunctioning location and perform the repair completion verification.

• If there is no malfunction:

-

― Replace the A/C compressor and perform the repair completion verification. (Internal circuit open)

|

|

9

|

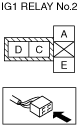

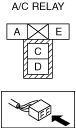

INSPECT A/C RELAY FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

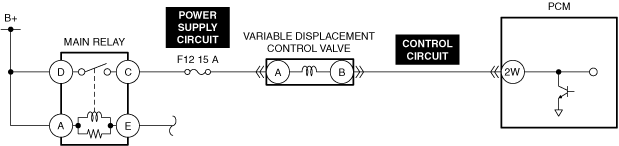

INSPECT VARIABLE DISPLACEMENT CONTROL VALVE POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT VARIABLE DISPLACEMENT CONTROL VALVE CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Variable displacement control valve can be considered the cause.

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, replace the A/C compressor and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|