|

1

|

VERIFY AIRFLOW CONDITION

• Switch the ignition ON (engine off or on).

• Set the airflow volume control dial to 1 or more.

• Does air flow from the vent after operating the blower motor?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 1 of the following troubleshooting.

|

|

2

|

INSPECT A/C COMPRESSOR OPERATION

• Start engine.

• Turn A/C switch on.

• Does A/C compressor operate?

|

Yes

|

Go to Step 1 of the following troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY DTCs FOR RELATED MODULES

• Verify DTCs using the M-MDS.

-

― Dash-electrical supply unit

― Body control module (BCM)

• Are any DTCs displayed?

|

Yes

|

Go to the applicable DTC inspection.

― Dash-electrical supply unit

― Body control module (BCM)

|

|

No

|

Go to the next step.

|

|

4

|

VERIFY MAGNETIC CLUTCH OPERATION

• Access PCM PID A/C_SW using the M-MDS.

• Start engine.

• Turn the PID A/C_SW to ON from OFF using the M-MDS simulation function.

• Is the magnetic clutch engaged/disengaged according to the simulation function operation?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 9.

|

|

5

|

VERIFY MEASURED VALUE OF A/C PRESSURE SENSOR

• Access PCM PIDs AC_PRES_AFT_COMP and AC_PRES_BEF_EXP_VLV using the M-MDS.

• Monitor the AC_PRES_AFT_COMP and AC_PRES_BEF_EXP_VLV while turning on and off the air conditioner by switching the control panel.

• Are PIDs normal?

|

Yes

|

Go to Step 7.

|

|

No

|

Go to the next step.

|

|

6

|

INSPECT REFRIGERANT PRESSURE SENSOR

• Inspect the refrigerant pressure sensor.

• Is the refrigerant pressure sensor normal?

|

Yes

|

Inspect the following and repair or replace if necessary.

• Refrigerant charge amount (if refrigerant has discharged completely, replace receiver/drier( *1))

Perform the repair completion verification.

|

|

No

|

Replace refrigerant pressure sensor, then perform the repair completion verification.

|

|

7

|

VERIFY MEASURED VALUE OF EVAPORATOR TEMPERATURE SENSOR

• Access dash-electrical supply unit PID EVA_TMP using the M-MDS.

• Turn the climate control unit A/C switch on and off while the PID EVA_TMP is displayed.

• Is the PID normal?

|

Yes

|

Perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT EVAPORATOR TEMPERATURE SENSOR

• Inspect the evaporator temperature sensor.

• Is the evaporator temperature sensor normal?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between evaporator temperature sensor terminal and climate control unit terminal.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness.

Perform the repair completion verification.

|

|

No

|

Replace the evaporator temperature sensor, then perform the repair completion verification.

|

|

9

|

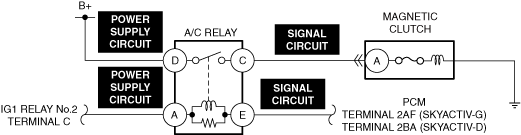

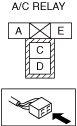

DETERMINE IF MALFUNCTION IS CAUSED BY A/C RELAY CIRCUIT MALFUNCTION OR PCM MALFUNCTION

• Short circuit between A/C relay terminal E (A/C control signal) and ground.

• Is there cool airflow?

|

Yes

|

Repair the short circuit and go to the next step.

|

|

No

|

Go to Step 13.

|

|

10*

|

INSPECT A/C RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT A/C RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

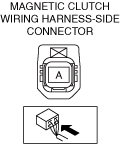

INSPECT MAGNETIC CLUTCH

• Inspect the magnetic clutch.

• Is the magnetic clutch normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the magnetic clutch, then perform the repair completion verification.

|

|

13*

|

INSPECT MAGNETIC CLUTCH POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit and short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

14*

|

INSPECT A/C RELAY POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the power supply circuit for an open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15*

|

INSPECT A/C RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16*

|

INSPECT MAGNETIC CLUTCH CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for open circuit.

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17*

|

INSPECT MAGNETIC CLUTCH CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Replace the A/C relay and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

Repair completion verification

|

VERIFY THAT MALFUNCTION SYMPTOM DOES NOT RECUR AFTER REPAIR

• Does cool air discharge from the vents? (Are the results of refrigerant system performance test normal?)

|

Yes

|

Troubleshooting completed. Explain repairs to customer.

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

If the CAN communication is normal, perform the diagnosis from Step 1.

|