|

1

|

DETERMINE IF MALFUNCTION CAUSE IS OVERHEATING OR OTHER

• Access the ECT PID using the M-MDS.

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

• Is the ECT PID value less than 116 °C {241 °F} during driving?

|

Yes

|

Go to the next step.

|

|

No

|

The cause of this concern could be from the cooling system overheating.

• Perform the symptom troubleshooting “COOLING SYSTEM CONCERNS-OVERHEATING”.

|

|

2

|

VERIFY PCM DTC

• Perform the DTC inspection for the PCM.

• Are any DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

VERIFY CURRENT INPUT SIGNAL STATUS

-

Warning

-

• While performing this step, always operate the vehicle in a safe and lawful manner.

• When the M-MDS is used to observe monitor system status while driving, be sure to have another technician with you, or record the data in the M-MDS using the PID/DATA MONITOR AND RECORD capturing function and inspect later.

• Access the following PIDs using the M-MDS:

-

― ECT

― ECT_VOLT

― ECT2

― ECT2_VOLT

― MAF

― MAP

― MAP_VOLT

― A/F_SEN_CUR

― HO2S_OUT_VOLT

― SHRT_FUEL_TRIM

― LONG_FUEL_TRIM

• Do the PIDs indicate the correct values under the malfunction condition?

|

Yes

|

Go to the next step.

|

|

No

|

ECT, ECT_VOLT, ECT2, ECT2_VOLT PIDs are not as specified:

• Inspect the ECT sensor No.1 and No.2.

MAF PID is not as specified:

• Inspect the MAF sensor.

MAP, MAP_VOLT PIDs are not as specified:

• Inspect the MAP sensor.

A/F_SEN_CUR, SHRT_FUEL_TRIM, LONG_FUEL_TRIM PIDs are not as specified:

• Inspect the A/F sensor.

HO2S_OUT_VOLT PID is not as specified:

Repair or replace the malfunctioning location.

• If the malfunction remains:

-

― Perform the “Action for Non-repeatable Malfunction” procedure.

|

|

4

|

DETERMINE IF MALFUNCTION CAUSE IS DRIVE-BY-WIRE CONTROL SYSTEM OR OTHER

• Will the engine run smoothly at part throttle?

|

Yes

|

Go to Step 6.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT DRIVE-BY-WIRE CONTROL SYSTEM OPERATION

• Perform the Electronic Control Throttle Operation Inspection.

• Does the drive-by-wire control system work properly?

|

Yes

|

Visually inspect the throttle body (damage/scratching).

• If there is any malfunction:

-

― Repair or replace the malfunctioning location and perform the repair completion verification.

• If there is no malfunction:

-

― Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT FUEL INJECTOR OPERATION

• Perform the Fuel Injector Operation Inspection.

• Do the fuel injectors operate properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT PURGE CONTROL SYSTEM OPERATION

• Perform the Purge Control System Inspection.

• Does the purge solenoid valve work properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT MAF SENSOR

• Inspect the MAF sensor for the following:

-

― Contamination

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

9

|

INSPECT PCM FOR POOR GROUND

• Verify the PCM ground point condition.

• Is there any ground point loose or lifting in the PCM?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT RELATED PART CONDITION

• Inspect the following:

-

― Fuel quality (proper octane, contamination, winter/summer blend)

― Fuel leakage

― Intake-air system leakage or restriction

― Vacuum leakage

― Engine oil viscosity

― CKP sensor, intake CMP sensor and exhaust CMP sensor

-

• Damaged trigger wheel, intake camshaft and exhaust camshaft

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

11

|

INSPECT FUEL PRESSURE (HIGH-SIDE)

• Start the engine and warm it up completely.

• Access the FUEL_PRES PID using the M-MDS at idle.

• Is the FUEL_PRES PID value within specification?

Specification:

• Approx. 40—60 MPa {408—611 kgf/cm2, 5,802—8,702 psi}

|

Yes

|

Go to Step 15.

|

|

No

|

FUEL_PRES PID value is lower than 40 MPa {408 kgf/cm2, 5,802 psi}:

• Inspect the following:

-

― Fuel leakage at the fuel line and fuel injector

― Fuel pump

-

• Perform the Fuel Pump (Low-pressure Side) Operation Inspection.

― High fuel pressure sensor

― High pressure fuel pump

• If there is any malfunction:

-

― Repair or replace the malfunctioning location and perform the repair completion verification.

• If there is no malfunction:

-

― Go to Step 14.

FUEL_PRES PID value is higher than 60 MPa {611 kgf/cm2, 8,702 psi}:

• Go to the next step.

|

|

12

|

DETERMINE IF MALFUNCTION CAUSE IS HIGH FUEL PRESSURE SENSOR OR HIGH PRESSURE FUEL PUMP

• Is the vehicle acceleration performance normal?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 14.

|

|

13

|

INSPECT HIGH FUEL PRESSURE SENSOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to Step 15.

|

|

No

|

Replace the fuel distributor and perform the repair completion verification.

|

|

14

|

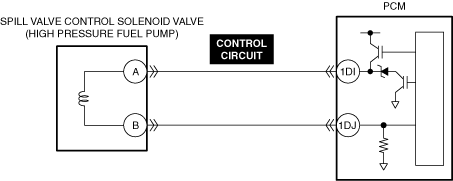

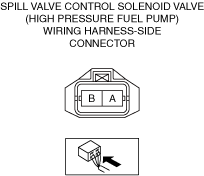

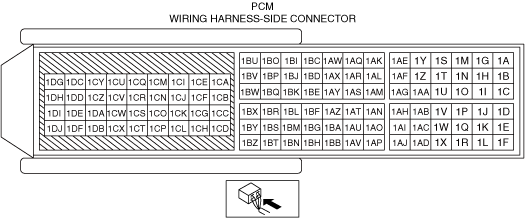

INSPECT SPILL VALVE CONTROL SOLENOID VALVE CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground.

• Is the circuit normal?

|

Yes

|

Replace the high pressure fuel pump and perform the repair completion verification.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15

|

INSPECT FUEL PRESSURE (LOW-SIDE)

• Connect the fuel pressure gauge between fuel pump and high pressure fuel pump.

• Measure the low side fuel pressure.

• Is the low side fuel pressure within specification?

Specification:

• 545—695 kPa {5.56—7.08 kgf/cm2, 79.1—100.0 psi}

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the following:

• Fuel line restriction

• Fuel filter clogged

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location and perform the repair completion verification.

― If there is no malfunction:

-

• Replace the fuel pump unit and perform the repair completion verification.

|

|

16

|

INSPECT STARTING SYSTEM

• Inspect the starting system.

• Does the starting system work properly?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

INSPECT ENGINE COMPRESSION

• Measure the compression pressure for each cylinder.

• Are compression pressures within specification?

|

Yes

|

Go to Step 22.

|

|

No

|

Go to the next step.

|

|

18

|

INSPECT INTAKE ELECTRIC VARIABLE VALVE TIMING DRIVER OR EXHAUST ELECTRIC VARIABLE VALVE TIMING DRIVER FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

19

|

INSPECT INTAKE ELECTRIC VARIABLE VALVE TIMING MOTOR OR EXHAUST ELECTRIC VARIABLE VALVE TIMING MOTOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

20

|

INSPECT INTAKE ELECTRIC VARIABLE VALVE TIMING ACTUATOR OR EXHAUST ELECTRIC VARIABLE VALVE TIMING ACTUATOR FOR MALFUNCTION

• Inspect the applicable part.

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

21

|

INSPECT FOR MALFUNCTION DUE TO DEVIATED VALVE TIMING

• Inspect the valve timing (timing chain installation condition).

• Is the valve timing normal?

|

Yes

|

Inspect for the following engine internal parts:

• Cylinder

• Piston ring

• Intake valve

• Exhaust valve

• Such as cylinder head gasket

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Adjust the valve timing to the correct timing and perform the repair completion verification.

|

|

22

|

INSPECT IGNITION SYSTEM OPERATION

• Perform the Spark Test.

• Is a strong blue spark visible at each cylinder?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

23

|

INSPECT EXHAUST SYSTEM FOR RESTRICTION

• Inspect for restriction in the exhaust system and the catalytic converter.

• Is there any restriction?

|

Yes

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

No

|

Go to the next step.

|

|

24

|

INSPECT IF MALFUNCTION CAUSE IS PCV VALVE OR INJECTOR DRIVER (PCM INTEGRATED)

• Is there any malfunction?

|

Yes

|

Replace the PCV valve and perform the repair completion verification.

|

|

No

|

Injector driver malfunction.

If the problem remains, overhaul the engine and perform the repair completion verification.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Has the malfunction symptom been eliminated?

|

Yes

|

Complete the symptom troubleshooting. (Explain contents of repair to customer)

|

|

No

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

• If the CAN communication is normal, perform the diagnosis from Step 1.

-

― If the malfunction recurs, go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF MALFUNCTION IS CAUSED BY NOT PERFORMING PCM REPROGRAMMING

• Verify repair information and verify that there is a new calibration in the PCM.

• Is there a new calibration in the PCM?

|

Yes

|

Perform the PCM reprogramming and verify if the malfunction symptom was corrected.

• If the malfunction recurs, replace the PCM.

|

|

No

|

Replace the PCM.

|